Baldwin builds curing and drying systems that are used in printing and other industrial applications to cure (solidify) or dry inks, coatings, treatments, adhesives and polymers.

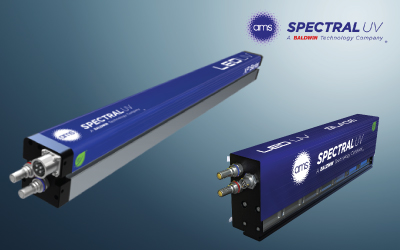

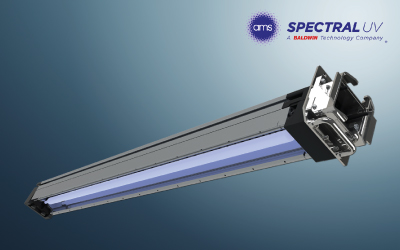

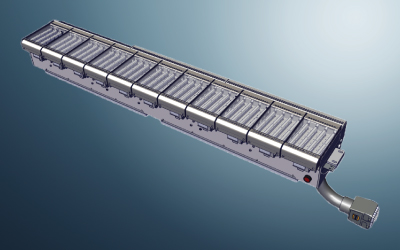

Our LED and UV systems offer the highest curing intensities available for printing and industrial curing today, thanks to patented technologies that are years ahead of competitors’ designs. Our drying technologies & applications offer the most efficient operation of their type available on the market, and we manufacture both bar-style dryers and standalone drying units through which your web or substrate can be fed and dried.

We manufacture energy-efficient drying and curing systems that are most commonly used in printing to dry or cure inks, coatings & three dimensional objects - many in the printing industry are familiar with our brand AMS Spectral UV, which produces the revolutionary technologies of legacy brands like Air Motion Systems and Nordson UV. With more than 10,000 IR systems and thousands of UV and LED systems installed around the world, Baldwin provides a turnkey service and support structure that is unmatched by our competitors, and that our customers appreciate every day.

Additionally, Baldwin offers the drying-solutions portfolio of our brand Ahlbrandt, which provides options for film-extrusion lines and other industrial drying situations.

UV curing lamps are also a Baldwin product.

View all of Baldwin’s solutions for industrial curing in this brochure.

Baldwin’s LED/UV/IR technology is used in a number of industries, including:

Web Offset Printing

Sheetfed Offset Printing

Newsprint

Corrugated Printing

Flexography

Digital Printing

Gravure

Screen Curing

Industrial Curing

What our customers customers say:

“With LED, we don’t need powder or protective coatings”

— Mark S., Schneider AG, Switzerland

“We’ve seen a 35-40% productivity gain with LED”

— Shiro T., Kinmei Printing, Japan

“We can now do in 7 hours what used to take us 12 ”

— Andre A., Adler Druck, Germany